Polythene & Rope

Polythene and Tunnel Rope are crucial components of polytunnels and are recommended to be changed on structures every 3-5 years.

We also understand the unpredictable weather events that we get in this country so during these unfortunate times, we ensure our operations team is primed and ready to go for fast dispatch from our warehouse if any of our customers require a tunnel/s to be re-skinned.

Traditionally we stock the following lengths and widths in various varieties:

10.7m width which is used for 8m & 8.5m tunnel bay width. Rolls start at 200m and go up to 800m long.

11.2m width which is used for 9m tunnel bay width. Rolls start at 200m and go up to 600m long.

Other widths are available upon request.

Are you choosing the right polythene?

Regardless of whether you are covering new or existing structures, from the moment a seedling emerges, light quality dictates exactly how it continues to develop. Many different factors play a part in making that plant productive; the quality of the light is potentially the most important, but often the hardest to manage. This is why we are always trialling different polythene on our own farms to maximise crop performance, and we’re constantly looking for a balance between light transmission, diffusion, thermicity & impact resistance for optimal return on investment.

There are several factors to consider when selecting polythene to maximise crop performance. We can help you select the correct balance of light transmission, diffusion, thermicity & impact resistance for optimal return on investment. Our polythene ranges from 8m to 15m wide and is sold in roll lengths of 200m, 400m, 600m and 800m.

Striking the balance:

Diffusion

Diffusion level is the extent of which light scatters as it passes through the polythene. Dispersing the light allows it to penetrate deeper into the crop canopy and reduces shading within the tunnel.

- High diffusion film is typically used for summer production where growers want to reduce heat stress and scorching on the plants to optimise yield and fruit size throughout the season.

- Low diffusion film is more effective at the start of the season when growers are looking to maximise light levels and earliness.

Haygrove supply polythene with a range of diffusion levels to suit your growing needs.

Light Transmission

Light transmission on new Haygrove polythene is always greater than 87%. As polythene ages, the UV rays break down the polythene to reduce the light transmission. This is further reduced by dust and algae build-up. Studies have shown that a 1% reduction in light transmission can lead to a 1% drop in yield.

UV transmission

UV light has significant beneficial effects on colour, levels of antioxidants, flavour, shelf life and hardiness. Bees navigate using UV light meaning that ‘UV open’ films can increase pollination rates.

Thermicity

Thermicity is the efficiency of reflecting infrared light. A thermic film can significantly reduce heat-build in tunnels during hot days, but also reduces heat escaping the tunnels on cold nights. The result is reduced temperature spikes, creating a more consistent climate for plants.

Strength

The thickness relates to the physical strength of the polythene. The choice of thickness is determined by how long it is expected to last and what mechanical pressure it needs to endure. Haygrove supply polythene in a range of thicknesses.

Recycling

We’re aware that as an industry we use a lot of polythene, and we are committed to ensuring that all of it gets recycled.

We actively encourage the recycling of tunnel film at the end of its primary lifecycle so that it can continue to add value by being recycled into other useful products such as crop grow bags or compost sacks. Recycling tunnel films ‘closes the loop’. Recycling film in country also cuts shipping emissions which further contributes to a sustainable horticulture industry.

7 layer Technology

7 Layer Technology films maximise individual performance characteristics such as UV transparency, temperature control and anti-fog properties by enabling the precision placement of high-performance polymers and additives within the overall film structure. With 7 layers, additives and other raw materials can be inserted with greater precision to create dedicated film layers for enhanced optic, thermic or strength attributes. This level of control means that the benefits of one feature are not offset by another. It enables the manipulation of a film blend in order to develop films that are bespoke to specific crops, climates or applications.

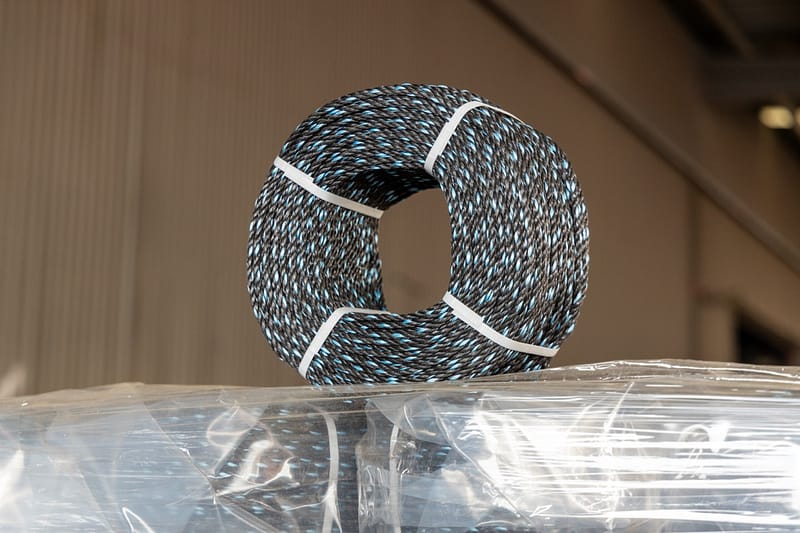

Rope