Growing substrate

Standard substrate parts kept at our Melbourne warehouse is as per below:

- 1.8m Gutter Legs

- 3m Leg Spacing

- All Bracketry for Single & Double row gutters

- End of row Caps with downpipe

- Steel coil for gutters

- Mesh, tape and all other parts required for a full growing system

We wish to provide our customers with complete and sustainable growing systems. The system must be integrated in design with the polytunnel, for maximum efficiency and output. Our range of products reflects the result of working with leading growers, including our own, to develop innovative systems that meet their needs.

Why Haygrove Substrate?

As part of our effort to supply customers with complete and sustainable growing systems, Haygrove substrate systems have been integrated in design with the polytunnel, for maximum efficiency and crop output.

- Developed with leading growers and tested on our own farms.

- A combination of our growing experience and a wealth of shared knowledge from our global partners enables Haygrove products to incorporate latest thinking in a fast-moving environment.

Increase in Yield and Quality

Substrate production allows precision irrigation, improved field hygiene and well-presented fruit. Combined with high quality coir, these factors allow growers to increase the uniformity, yield, and quality of the crop and maximise the return on the investment.

Increase labour efficiency

Labour cost and availability is at the forefront our industry’s mind. Substrate grown strawberries have the potential to significantly reduce labour requirement in both harvest and non-harvest operations. Investing in substrate systems has immediate benefits but also prepares conditions to the evercloser reality of automated picking.

Building the right system for your needs

Depending on the crop you’re growing, climate you’re farming in and the method you’re using, our substrate range provides a variety of options to help maximise yield.

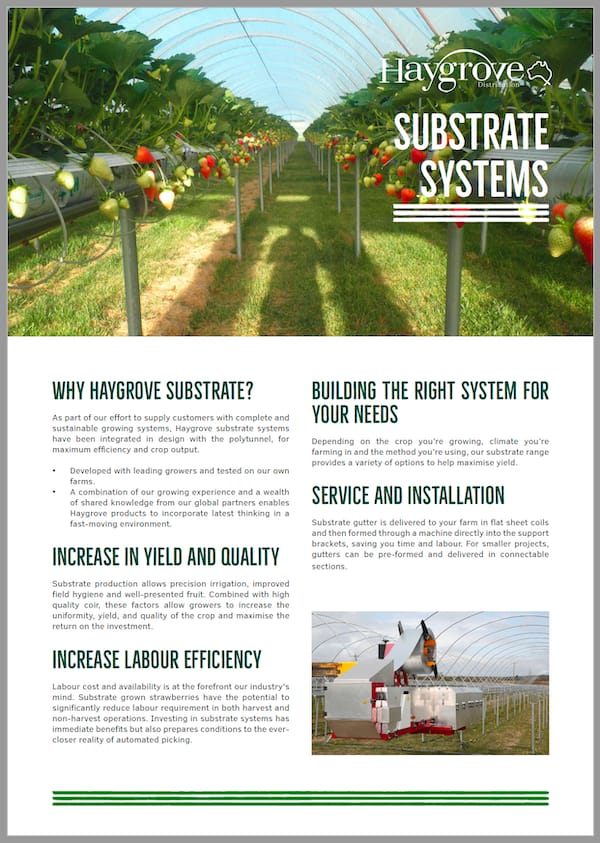

Service and Installation

Substrate gutter is delivered to your farm in flat sheet coils and then formed through a machine directly into the support brackets, saving you time and labour. For smaller projects, gutters can be pre-formed and delivered in connectable sections.

Row Configuration

There are three row configuration options. Choosing the right system for you depends on climate, level of solar radiation and crop variety

Single Row

Designed to provide a glasshouse quality system for tunnel growers. As an example, this substrate system in an 8.5m wide tunnel delivers 7,050 linear meters per hectare.